Choosing the Right Sign Substrate:

A Deeper Dive

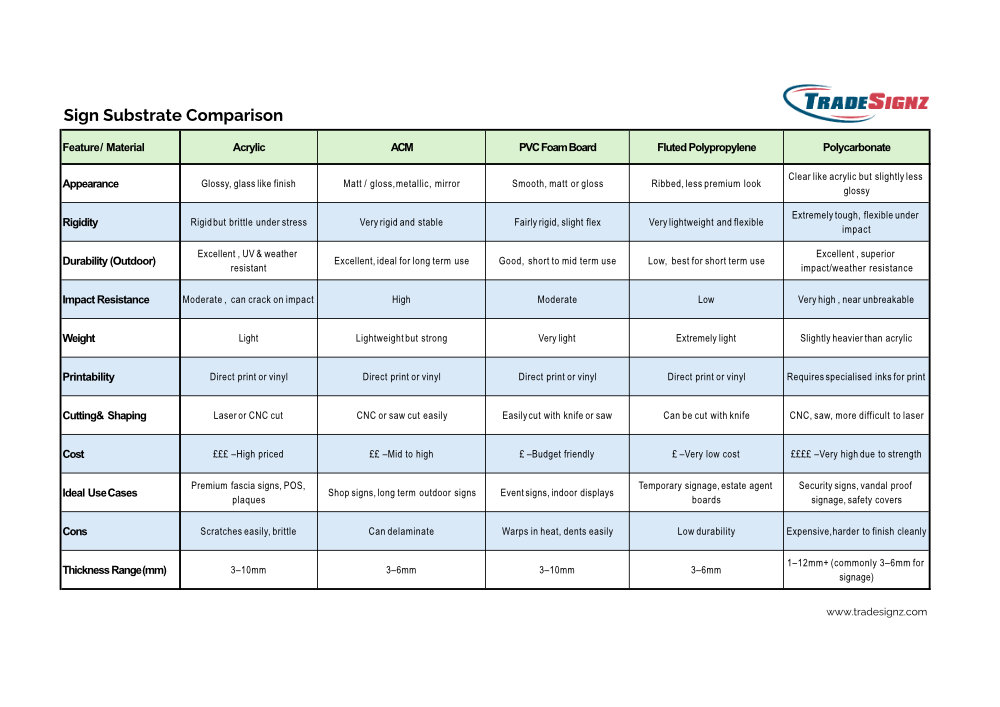

Following on from our guide, "Choosing the Right Sign Substrate: A Guide for Signmakers", where we explored the most popular sign materials and their ideal applications. Now, we’re taking things a step further. This deeper dive unpacks the differences between the substrates acrylic, ACM, PVC foam, Polypropylene & Polycarbonate, comparing their strengths, limitations and best use scenarios. Whether you're weighing up cost versus longevity, or aesthetics versus durability, this guide will help you make confident, informed choices tailored to your signage needs.

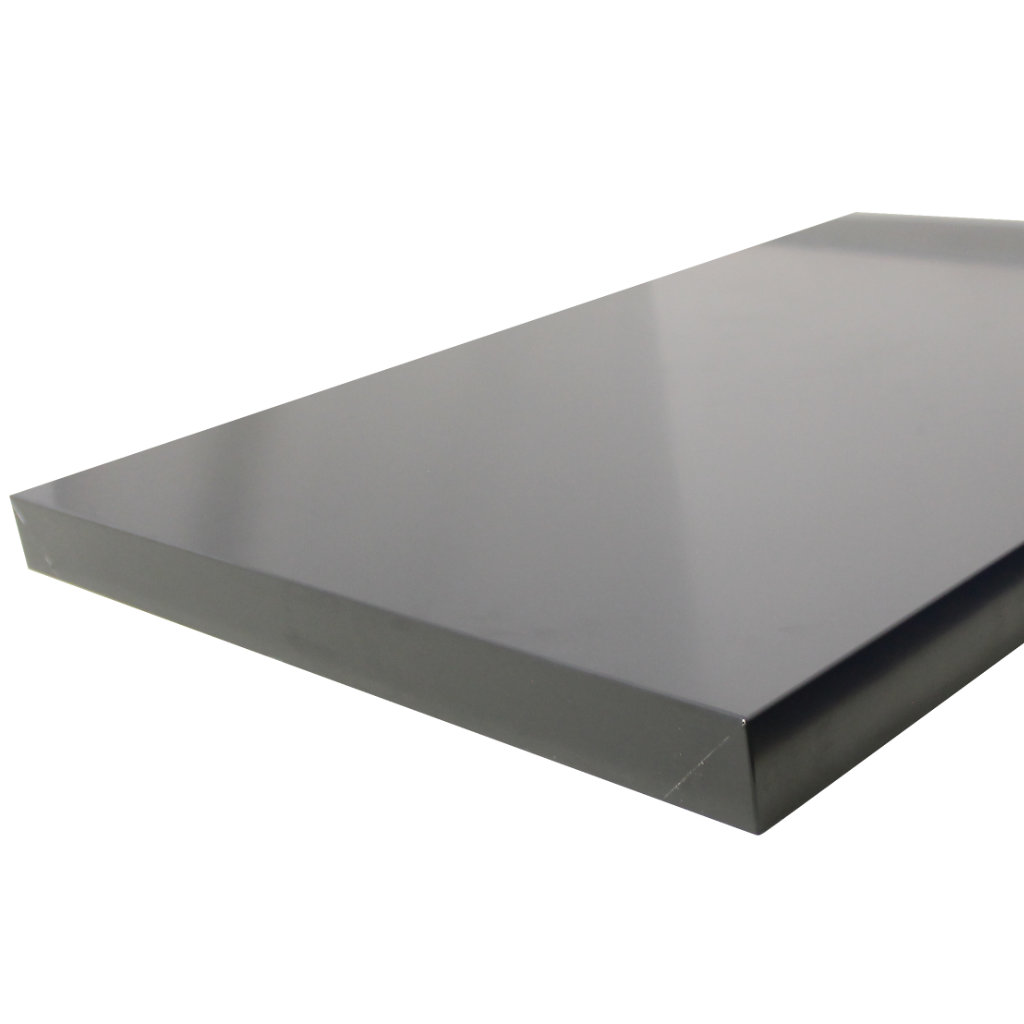

Acrylic Sheet

Common Uses of Acrylic Sheet in Sign Making:

Illuminated Signs

- Ideal for lightboxes and backlit signs as it provides high light transmission.

- Works well with LED lighting for clean, even illumination.

Retail and Shop Signage

- Used for polished, professional looking fascia signs, especially when branding is important.

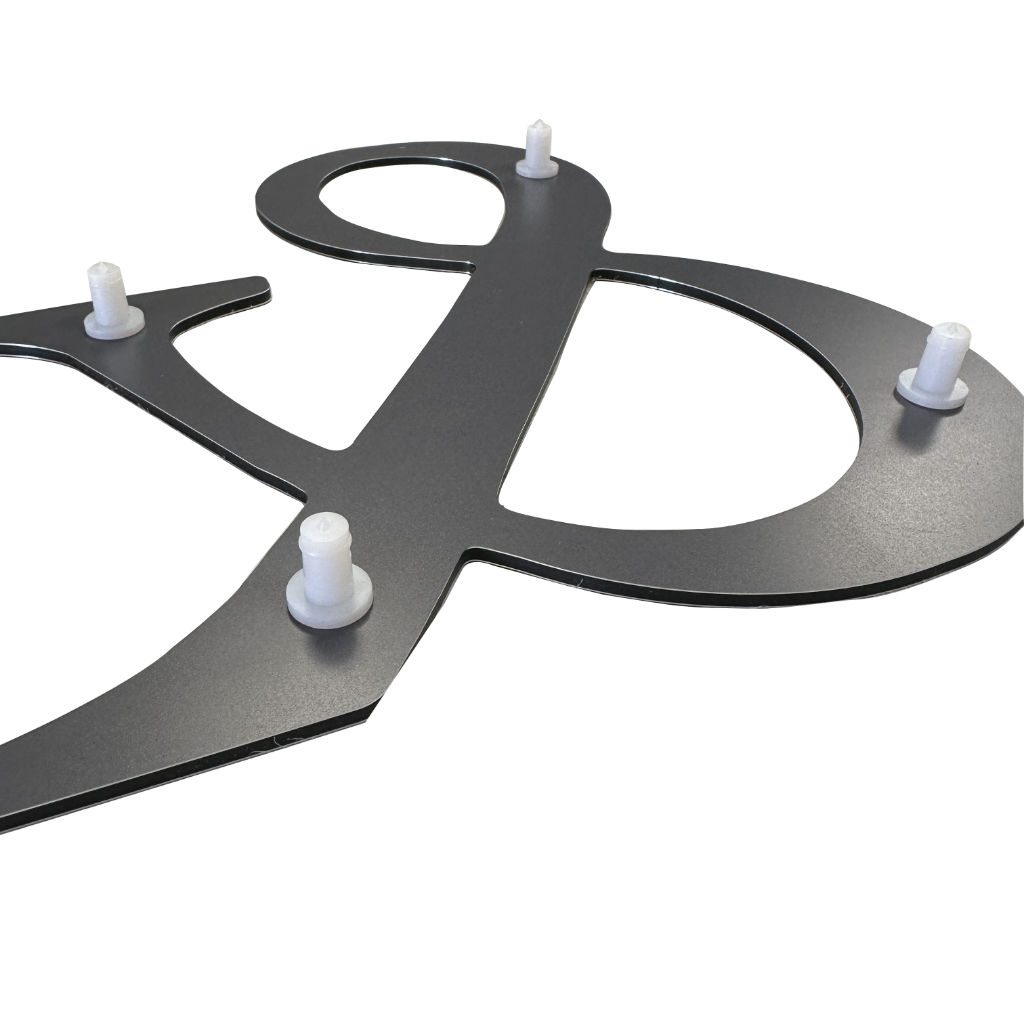

CNC Cut Letters and Logos

- Acrylic can be cut for intricate shapes, making it popular for 3D lettering and logos.

Point of Sale Displays

- Clear or coloured acrylic is commonly used for countertop displays, price holders and promotional signage.

Nameplates and Plaques

- Offers a clean, glass like finish for office and door signage.

Protective Sign Covers

- Transparent acrylic sheets are used to cover and protect graphics or posters in outdoor or high traffic areas.

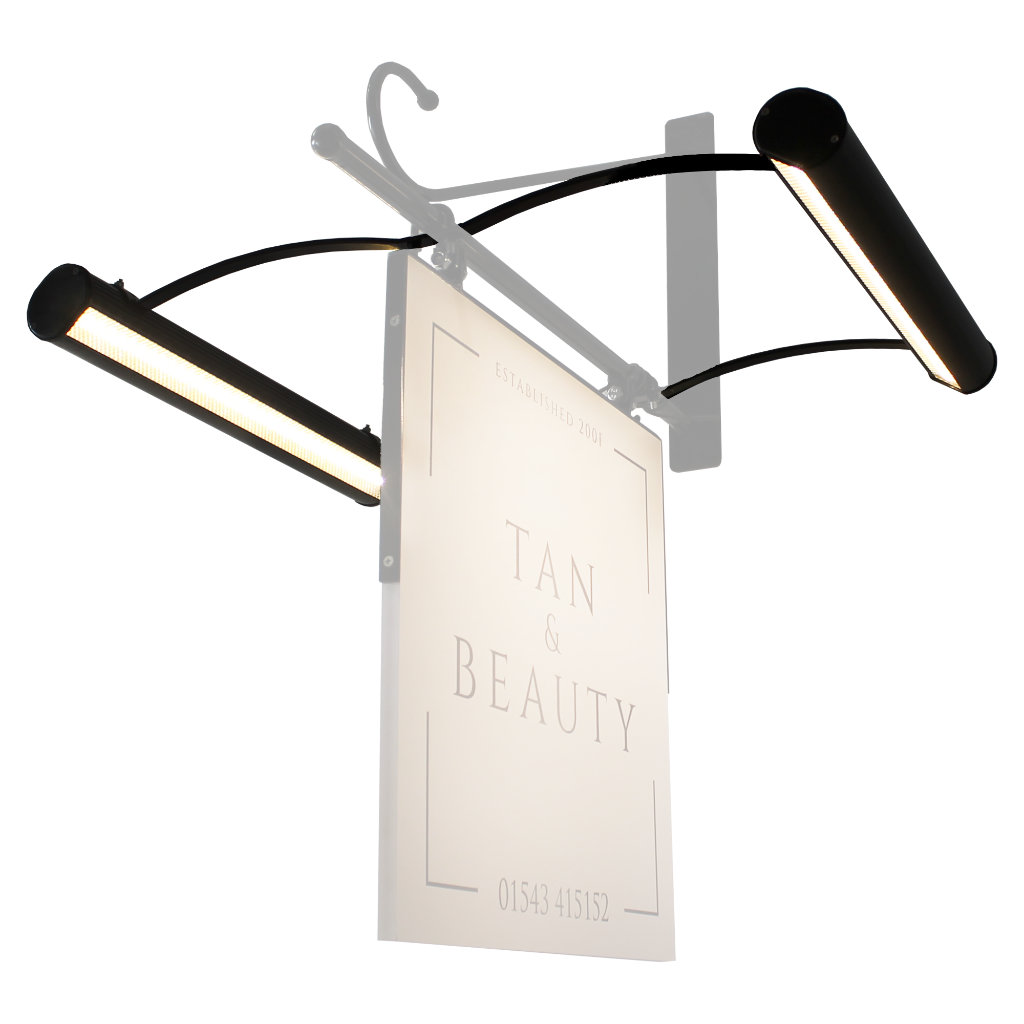

Standoff Signage

- Often used with metal standoffs to create sleek, floating style wall signs.

Pros of Acrylic Sheet

- High Visual Appeal Crystal clear or available in a range of colours and finishes (gloss, matte, frosted), offering a premium look.

- Lightweight vs. Glass Much lighter than glass but with a similar appearance, easier to install and transport.

- Weather & UV Resistant Suitable for outdoor signs; doesn’t yellow or degrade quickly in sunlight.

- Laser Friendly Cuts cleanly with laser machines, making it perfect for precision signage.

- Customisable Can be printed on, painted, engraved, or vinyl-wrapped depending on the job.

- Durable & Shatter Resistant More impact resistant than glass; won’t shatter easily, making it safer and longer-lasting.

Cons of Acrylic Sheet:

- Scratches Easily Surface is prone to scratching, needs care in handling, cleaning and installation.

- Brittle Under Stress Can crack if over tightened during fixing or subjected to bending forces.

- Static Attraction Attracts dust and particles due to static build-up, especially clear or black sheets.

- Higher Cost Than Some Alternatives More expensive than foam board, which might be better suited for short term signage.

- Thermal Expansion Expands and contracts with temperature changes, requiring allowances during installation.

Summary:

Acrylic is a go to material for high end signage due to its premium finish and versatility. It’s ideal for indoor and outdoor signs, especially where appearance and durability matter. However, for budget or temporary applications, it may be over specified compared to cheaper substrates like Foamex or Correx.

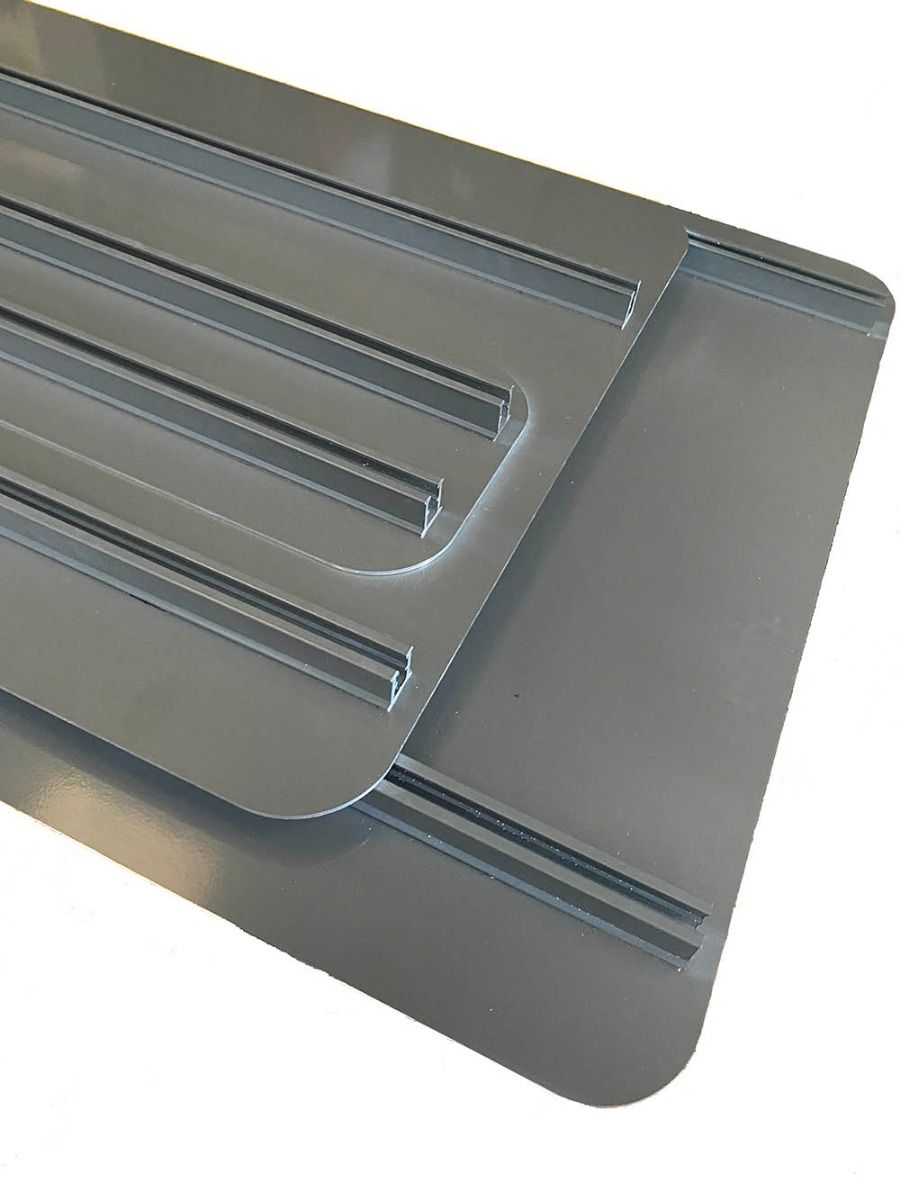

ACM

Common Uses of Acrylic Sheet in Sign Making:

Exterior Signage

- Building signs

- Fascia panels

- Wayfinding & directional signs

- Shopfronts

- Post & panel signs

Interior Signage

- Reception signs

- Display panels

- Menu boards

- Office branding

Printed Graphics & Wraps

- Ideal for full colour digital prints

- Often laminated or UV coated

Cut Lettering and Shape Cut Signs

- CNC routed for precision shapes and logos

Temporary & Event Signage

- Lightweight yet rigid, suitable for exhibitions

Pros of ACM

- Durability Weather-resistant (UV, rain, wind), it won’t warp or rust & has a long lifespan (5–10+ years outdoors)

- Lightweight It’s easier to handle, mount and install than solid aluminium or plywood

- Professional Appearance Offers a smooth, flat surface ideal for high quality prints and is available in various finishes: gloss, matt, brushed metal or mirror

- Workability ACM is easy to cut, route, and drill. It works well with vinyl graphics and direct printing.

- Cost-Effective Cheaper than solid metal panels & lower maintenance over time.

- Versatile Sizes and Colours Available in common thicknesses (e.g., 3mm) and in a wide range of RAL colours.

Cons of ACM

- Edge Delamination If mishandled or exposed to water at cut edges, layers may separate.

- Structural Limitations ACM is not load-bearing. It can flex under weight or pressure if unsupported across long spans.

- Heat Sensitivity The core (usually polyethylene) may deform under extreme heat so it is not suitable near open flames or high-heat environments

- Environmental Impact Polyethylene core isn’t biodegradable so the recycling options are limited.

- Cost More expensive than foam board or polypropylene for short-term use.

Summary:

ACM is a highly versatile and durable substrate commonly used for both indoor and outdoor signage. Its weather resistance, smooth surface, and lightweight structure make it ideal for building signs, retail panels, directional signage, and more. It’s easy to cut, drill and print on, offering a professional finish at a relatively affordable price. However, ACM has some downsides, such as potential edge delamination if improperly handled, limited structural strength, and environmental concerns due to its polyethylene core. Despite these drawbacks, its combination of durability, appearance, and ease of use makes ACM a go to material for long lasting, high quality signage.

PVC Foam

Common Uses of PVC Foam in Sign Making:

Indoor Signs

- Retail displays

- Wayfinding signs

- Point-of-purchase (POP) displays

- Office branding

Outdoor Signs (short to medium term use)

- Temporary construction signs

- Real estate signs

- Event signage

3D Lettering & CNC Routed Signs

- PVC foam cuts cleanly with routers, making it ideal for dimensional signage.

Digital & Screen Printing Substrate

- PVC Foam has a smooth, matt surface takes inks and vinyl very well.

Pros of PVC Foam

- Lightweight Easy to transport, handle and install, especially useful for large format signs.

- Cost-effective Less expensive than ACM or acrylic, especially for temporary signs.

- Printable Surface Excellent for UV flatbed printing, screen printing and vinyl application.

- Machinable Can be easily cut, drilled, or routed.

- Weather & Moisture Resistant Suitable for outdoor use (up to 3–5 years depending on conditions).

- Variety of Thicknesses & Colours Offers design flexibility.

Cons of PVC Foam for Sign Makers

- Not Ideal for Long Term Outdoor Use Can warp or degrade over time with prolonged UV exposure.

- Soft Surface More prone to scratches, dents and impressions compared to harder materials like acrylic or ACM.

- Flammability Though often flame-retardant, it can still release toxic fumes if burned.

- Structural Weakness Not suitable for load bearing applications or where rigidity is critical.

- Environmental Concerns Not easily recyclable, and its production has a relatively high environmental impact.

Summary

PVC foam board is a go- to material for many sign makers due to its low cost, light weight and adaptability for indoor and short term outdoor signage. While it’s not ideal for long term exposure or heavy duty applications, it remains a favourite for retail signs, displays and printed panels thanks to its smooth finish and ease of fabrication.

Polypropylene

Common Uses of Polypropylene (Correx) in Sign Making:

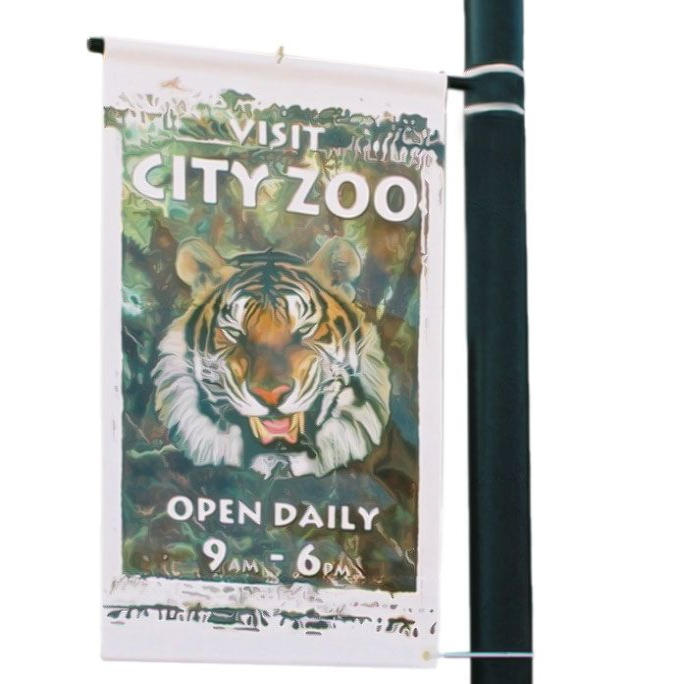

Temporary Outdoor Signs

- Estate agent signs

- Event signage (festivals, races, etc.)

- Construction site boards

Short-Term Indoor Signage

- POP displays

- Temporary promotional signage

- Exhibition panels

Pros of Polypropylene

- Very Cost-Effective: One of the cheapest rigid substrates available.

- Lightweight: Extremely light, making it easy to carry, mount and install.

- Weather Resistant: Water resistant and suitable for short-term outdoor use.

- Recyclable: More environmentally friendly than some plastics (can be recycled in certain facilities).

- Print Friendly: Can be printed on directly (usually UV flatbed) or have vinyl graphics applied.

- Quick Production: Cuts easily with a knife or guillotine, ideal for bulk signage.

Cons of Polypropylene

- Low Durability Bends, creases, or crushes easily, especially in windy or high contact areas.

- Fluted Structure The corrugated channels can make it structurally weak and less professional looking up close.

- Limited Aesthetic Appeal Visible flutes and matte plastic surface can look "cheap" for premium signage.

- Short Lifespan Degrades under prolonged sun exposure, colours can fade and board can become brittle.

- Not Ideal for Detail Cutting Fine CNC routing or complex shapes may not be precise due to fluted core.

Summary

Polypropylene fluted board is a sign maker’s budget friendly solution for temporary, high volume signage, especially outdoors. While not suited for premium, long term or structural signage, it’s the go to choice for estate agents and event signs where cost and speed matter most.

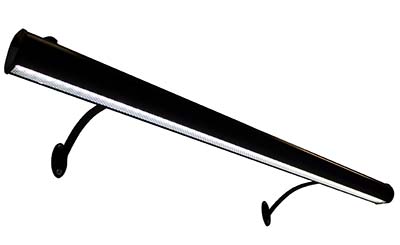

Polycarbonate

Common Uses of Polycarbonate in Sign Making

Backlit / Illuminated Signs

- Lightboxes

- Menu boards

Protective Panels

- Anti-vandal glazing for signs

- Face covers for LED displays or digital signs

Outdoor Permanent Signage

- Industrial signs

- Transportation and directional signage in high-impact areas

Formed or Moulded Signs

- Vacuum-formed polycarbonate sheets used for dimensional or illuminated signage

Pros of Polycarbonate

- Extreme Impact Resistance Virtually unbreakable—over 200x stronger than glass.

- High Clarity Offers excellent light transmission, making it ideal for backlit signs.

- Weather & UV Resistant Holds up well outdoors for many years, especially when UV coated.

- Thermoformable Can be heated and moulded for custom shapes or formed sign faces.

- Fire Retardant Better flame resistance than materials like acrylic.

- Graffiti Resistant Options: Available with protective coatings to reduce vandalism damage.

Cons of Polycarbonate

- Expensive Significantly more costly than acrylic, PVC, or polypropylene.

- Scratches Easily Softer surface than acrylic, requires hard coating for abrasion resistance.

- Not Ideal for Direct Printing Typically needs surface treatment or laminate for ink adhesion.

- Weight Heavier than acrylic and other plastics, which can impact mounting hardware or structural design.

- Yellows Over Time (Uncoated) Non-UV coated sheets may yellow or haze after prolonged sun exposure.

Summary

Polycarbonate is the premium choice for sign makers needing maximum durability, impact resistance and clarity, especially for backlit signs and vandal prone locations. While it’s more expensive and requires surface protection, its long lifespan and performance in harsh conditions make it ideal for high end, permanent signage.

View our Sign Substrate

Comparison Chart here >>