Wrought Iron - a brief description

Wrought iron is an iron alloy with a very low carbon (less than 0.08%) content in contrast to cast iron (2.1% to 4%).

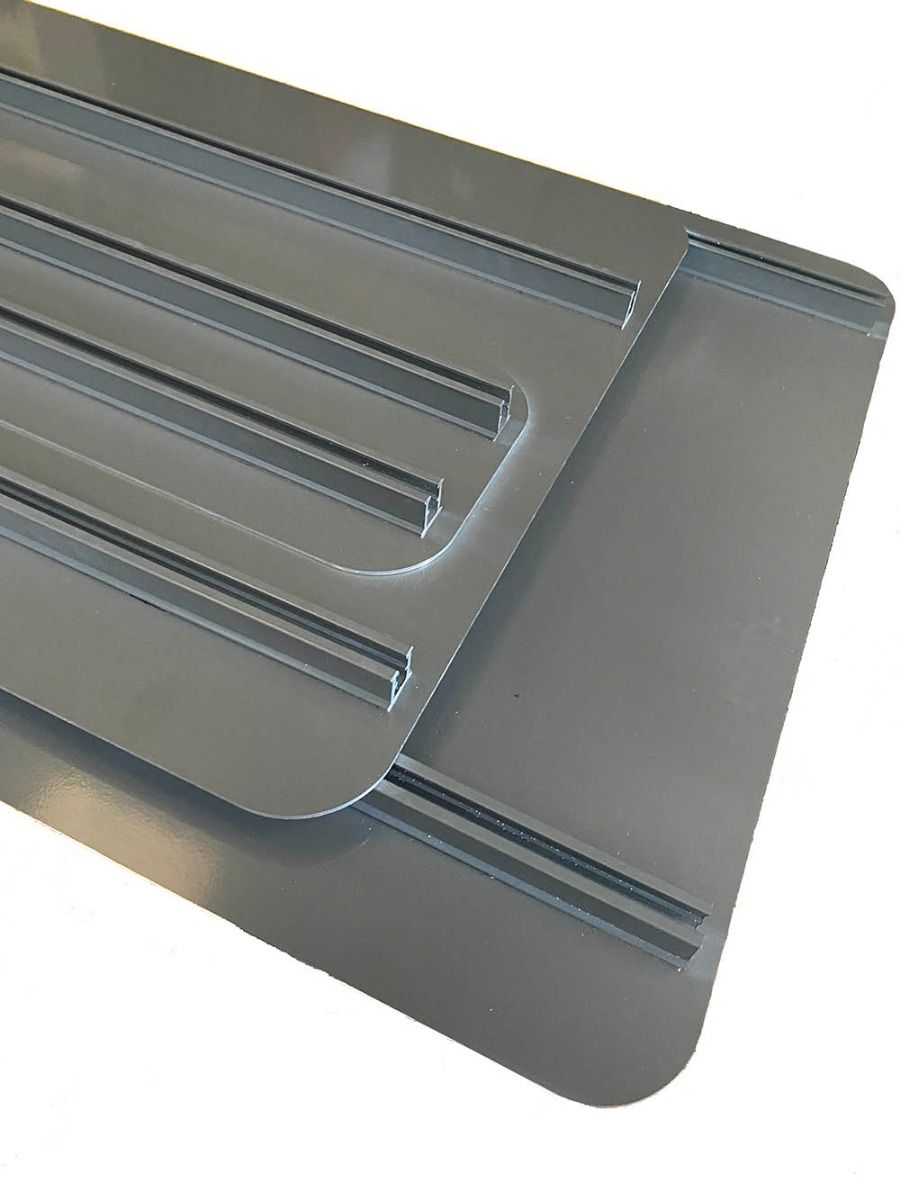

It has fibrous inclusions known as slag up to 2% by weight. It is a semi-fused mass of iron with slag inclusions which gives it a "grain" resembling wood, that is visible when it is etched or bent to the point of failure.

Wrought iron is tough, malleable, ductile, corrosion-resistant and easily welded. Before the development of effective methods of steelmaking and the availability of large quantities of steel, wrought iron was the most common form of malleable iron.

A modest amount of wrought iron was used as a raw material for refining into steel, which was used mainly to produce swords, cutlery, chisels, axes and other edged tools as well as springs and files.

The demand for wrought iron reached its peak in the 1860s with the adaptation of ironclad warships and railways. However, as properties such as brittleness of mild steel improved, it became less costly and more widely available than wrought iron, whose usage then declined.

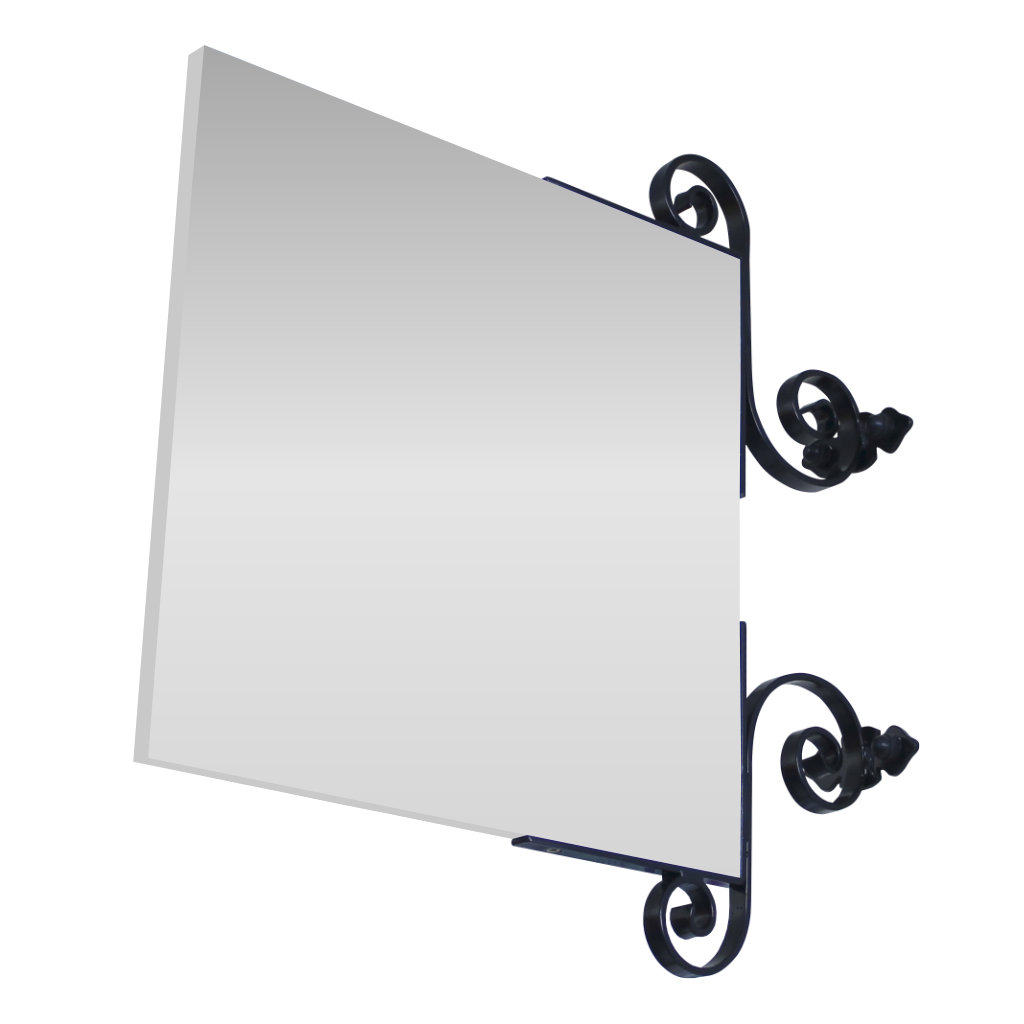

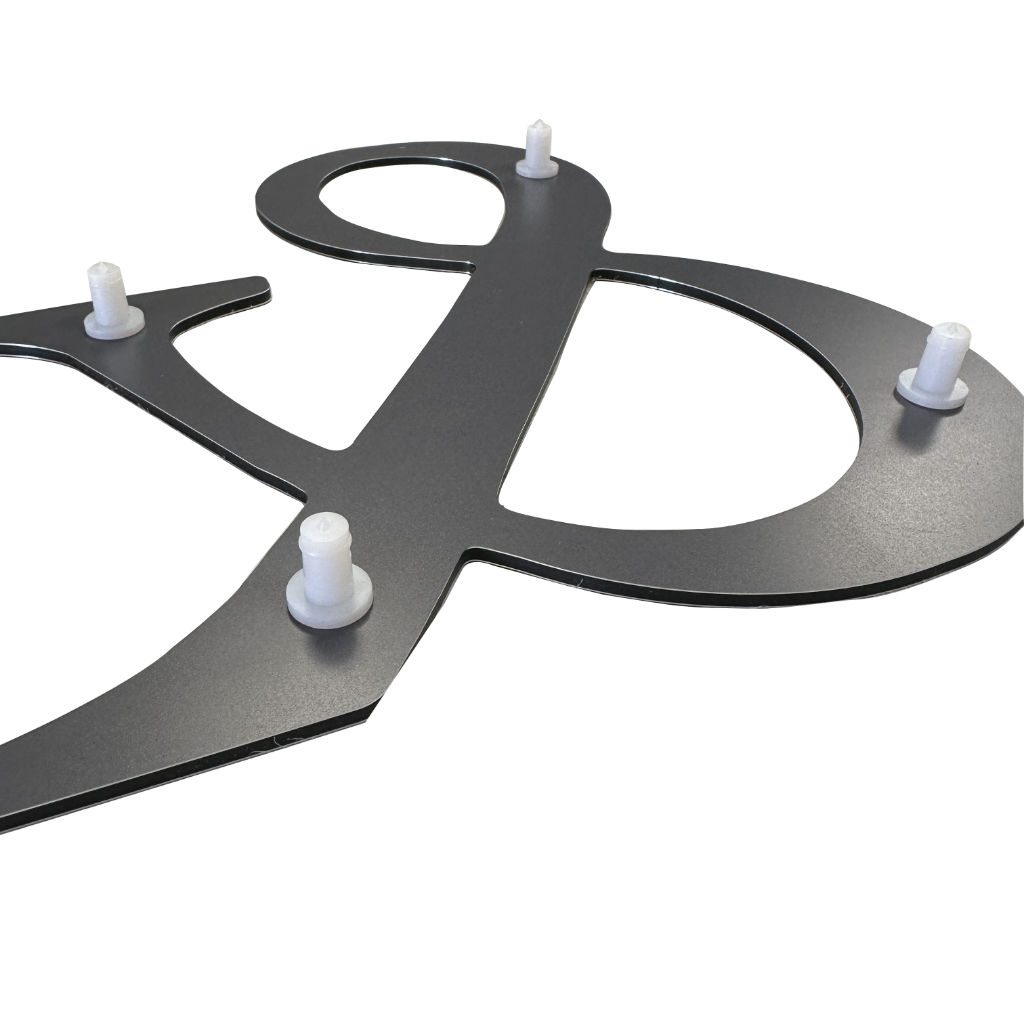

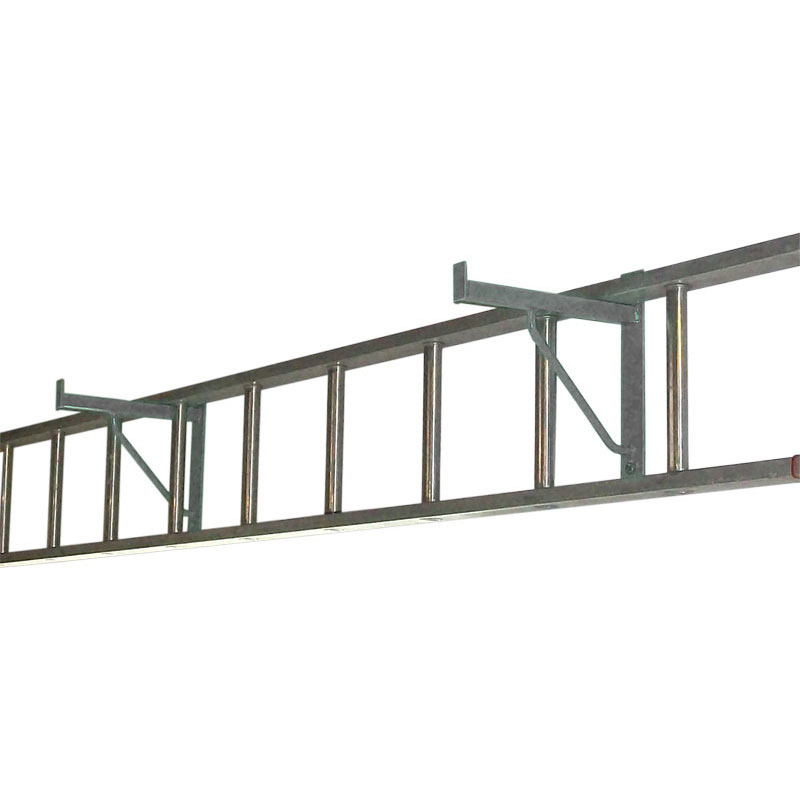

Many items, before they came to be made of mild steel, were produced from wrought iron, including rivets, nails, wire, chains, rails, railway couplings, water and steam pipes, nuts, bolts, horseshoes, handrails, wagon tires, straps for timber roof trusses, and ornamental ironwork.

Wrought iron is no longer produced on a commercial scale, although many products described as wrought iron, such as guard rails, garden furniture and gates, are actually made of mild steel.

They retain that description because in the past they were wrought (worked) by hand.