Why CNC Routing Is Changing the Game for Sign Fabricators

In the ever evolving world of signage, precision and speed are no longer luxuries, they’re expectations. As demand grows for bespoke, durable and visually striking signs, sign fabricators are turning to CNC routing to meet the challenge. But this isn’t just a case of upgrading machinery. CNC routing is fundamentally reshaping how signs are designed, produced and perceived. From streamlining workflows to unlocking creative possibilities, it’s changing the game and here’s why.

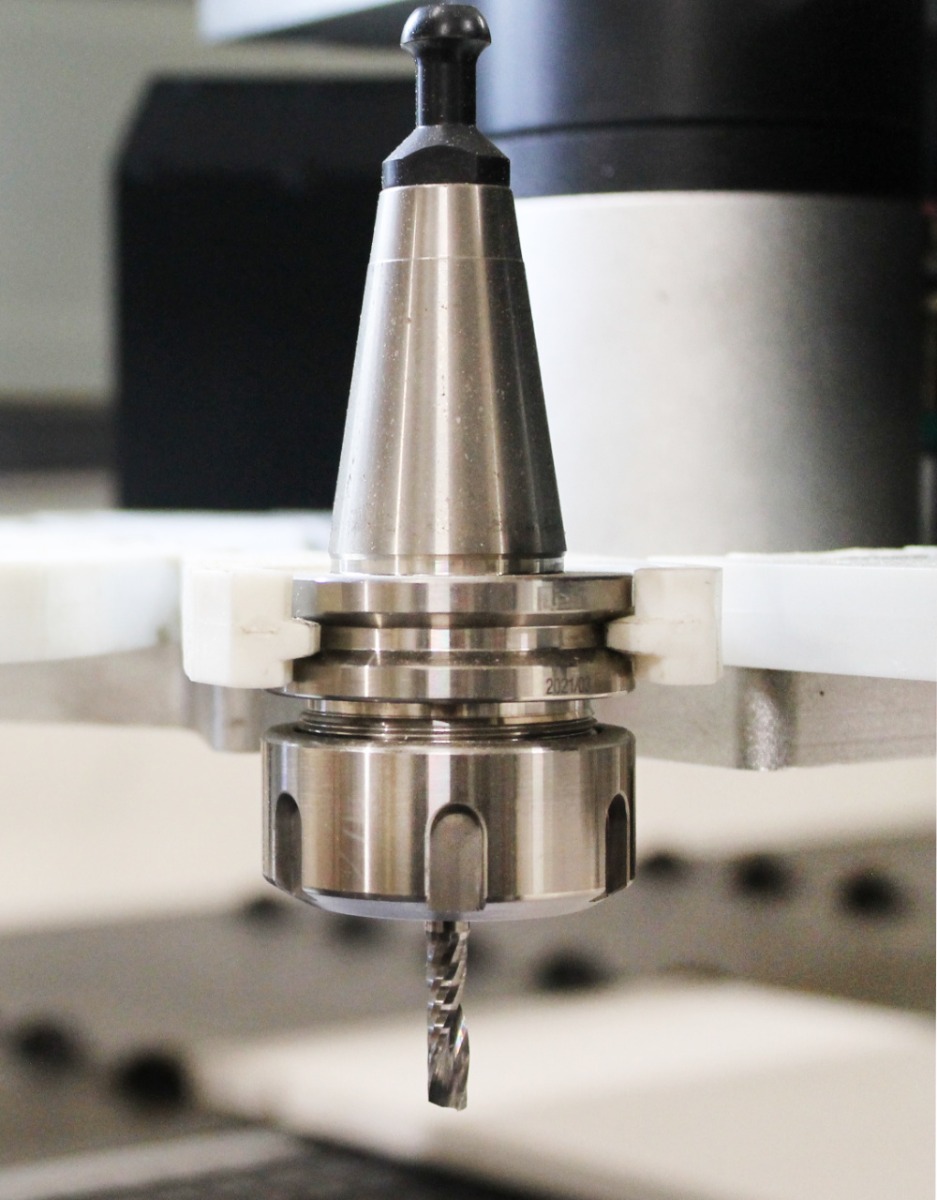

What Is CNC Routing?

CNC (Computer Numerical Control) routing is a subtractive manufacturing process where a computer controlled cutting tool carves, drills or engraves materials based on digital designs. Unlike manual routing, CNC machines follow precise coordinates, allowing for repeatable accuracy across complex shapes and patterns.

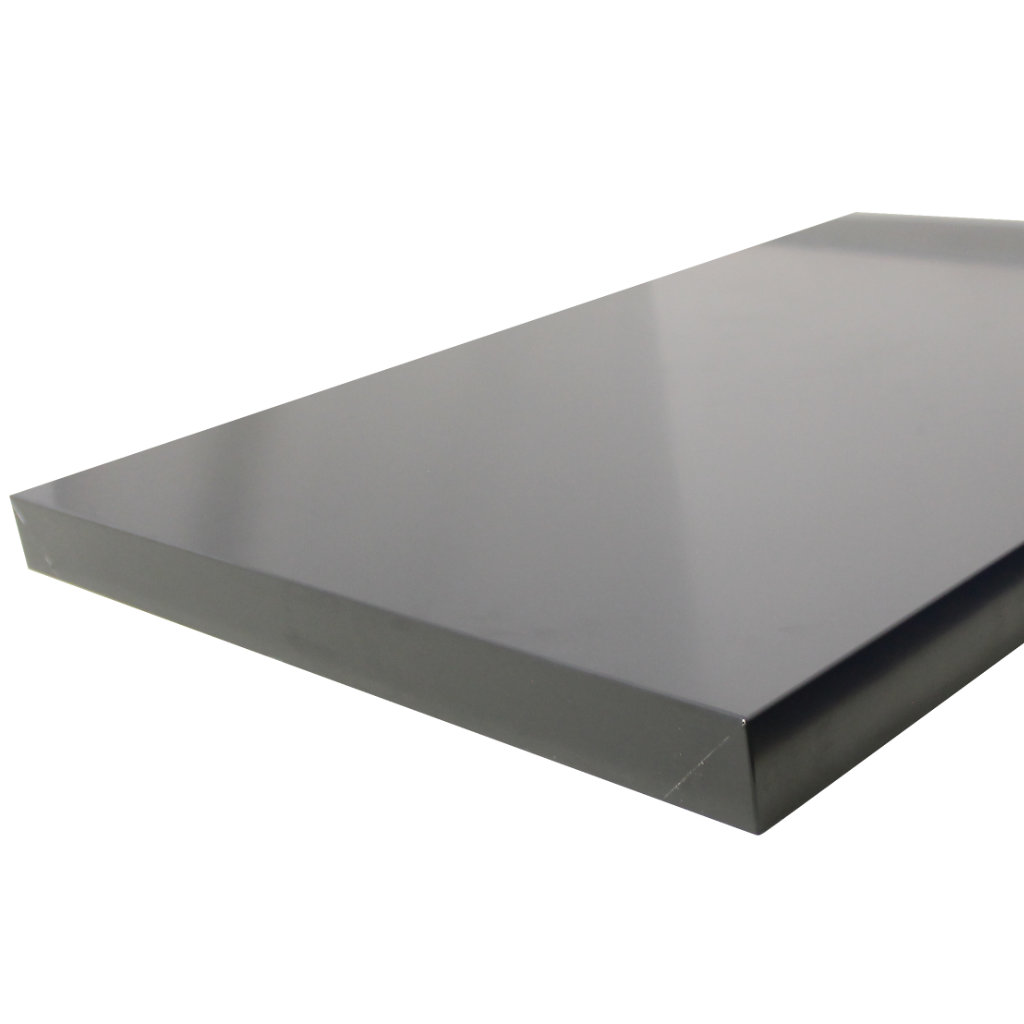

Materials commonly routed include:

- Aluminium Composite Material (ACM)

- Acrylics

- Wood and MDF

- Foam board

Whether it’s cutting out intricate lettering or creating panels, CNC routing delivers results that are clean, consistent and scalable.

Speed Meets Precision

One of the most immediate benefits of CNC routing is its ability to dramatically reduce production time without compromising quality. Traditional methods often involve manual cutting, sanding and finishing, each step introducing potential for human error. CNC routing eliminates that variability.

- Repeatability: Once a design is programmed, it can be reproduced hundreds of times with identical results.

- Efficiency: Complex cuts that might take hours by hand can be completed in minutes.

- Accuracy: Tolerances are often within fractions of a millimetre, ideal for tight fitting components and illuminated signage.

For sign fabricators juggling multiple projects, this means faster turnaround times and fewer costly mistakes.

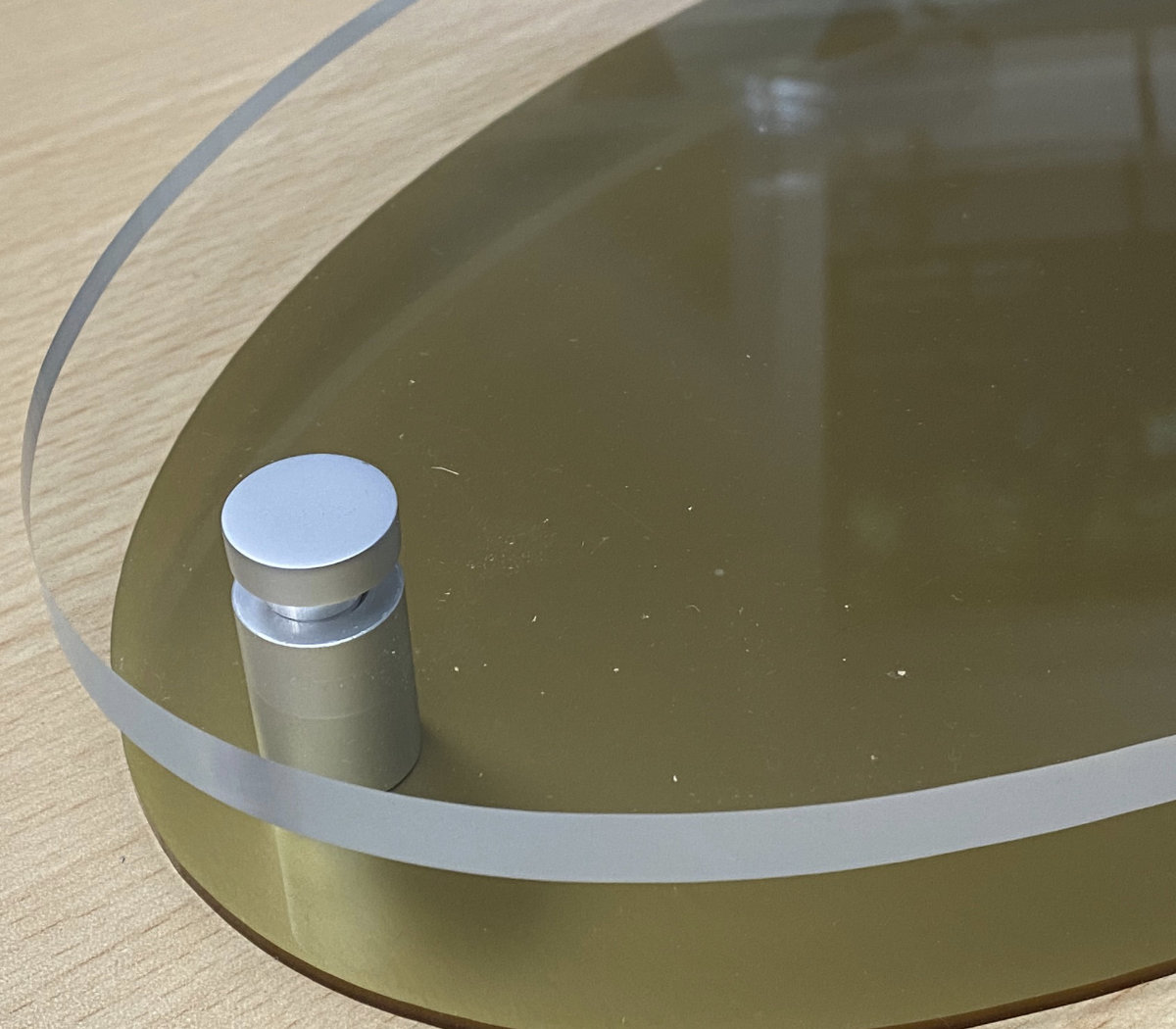

Creativity Unleashed

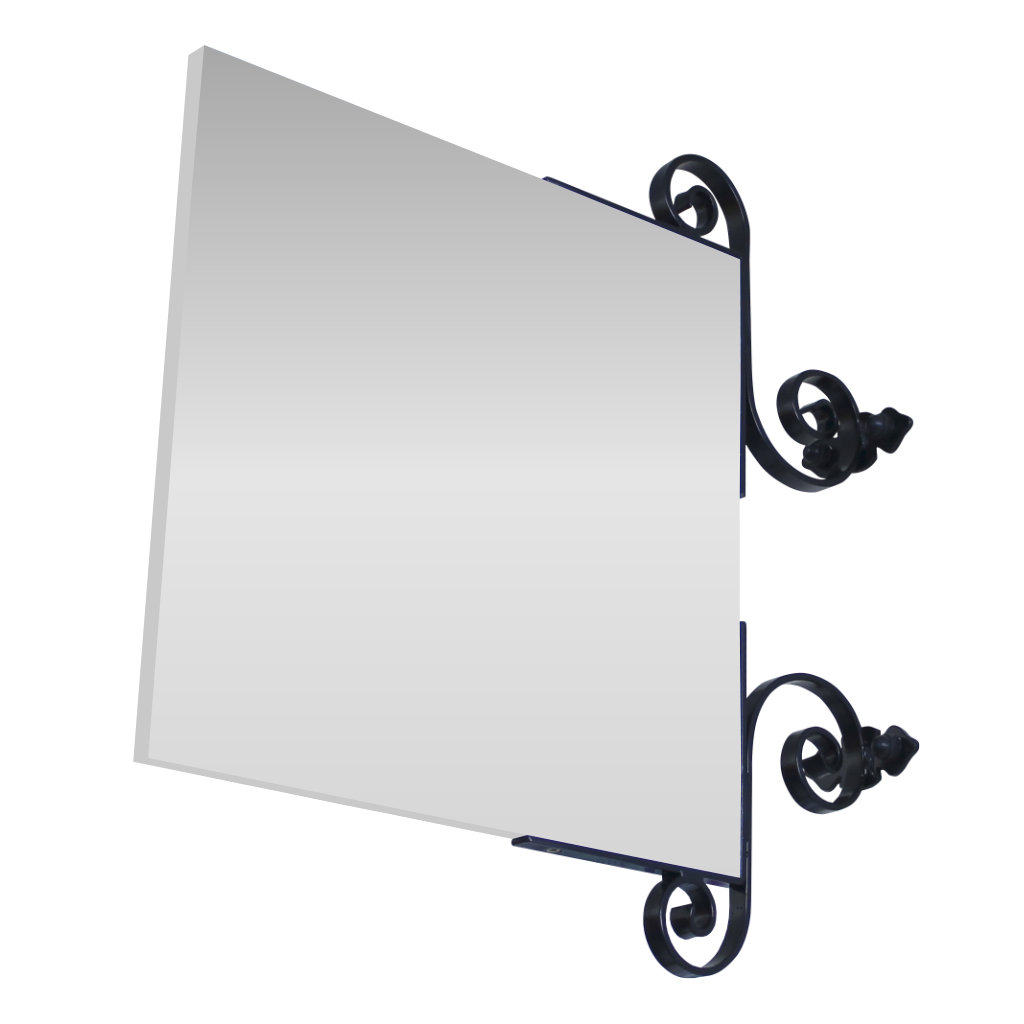

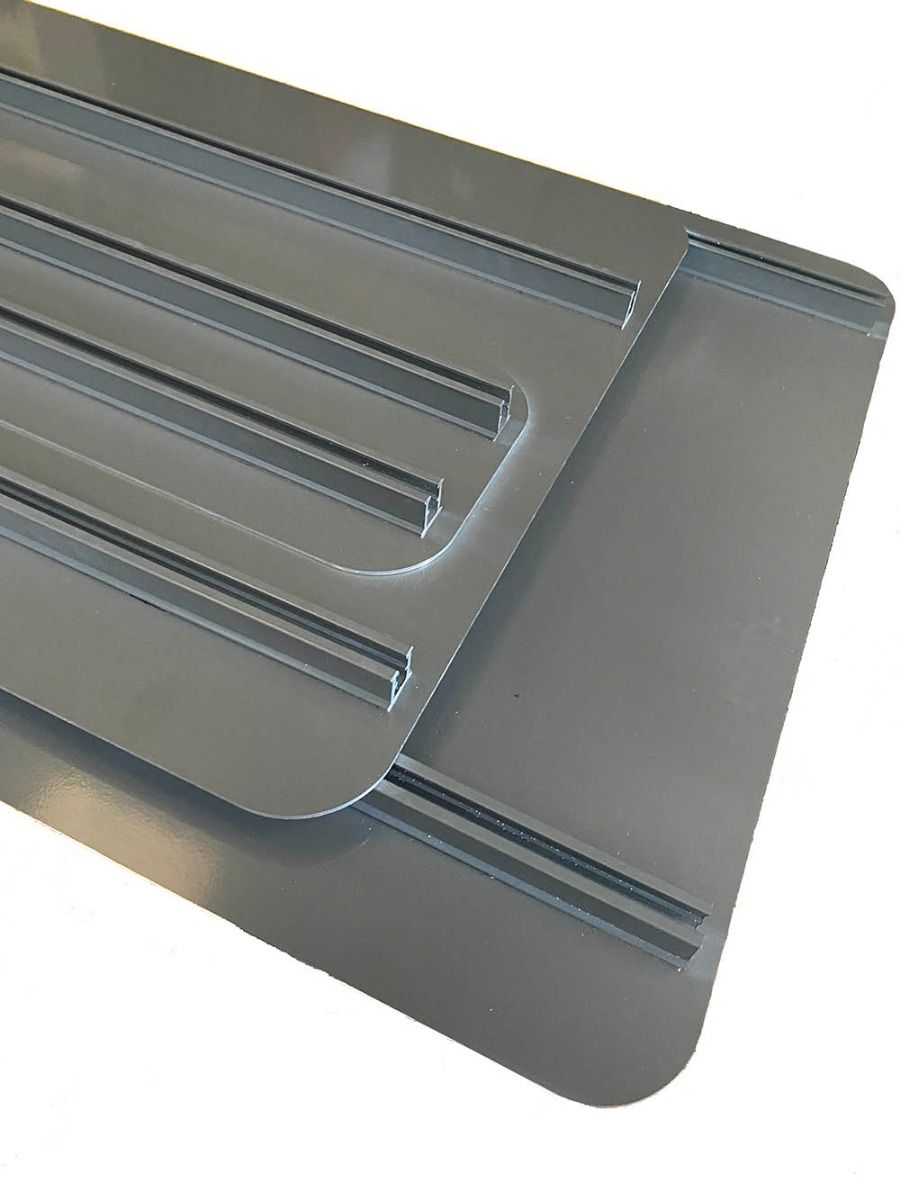

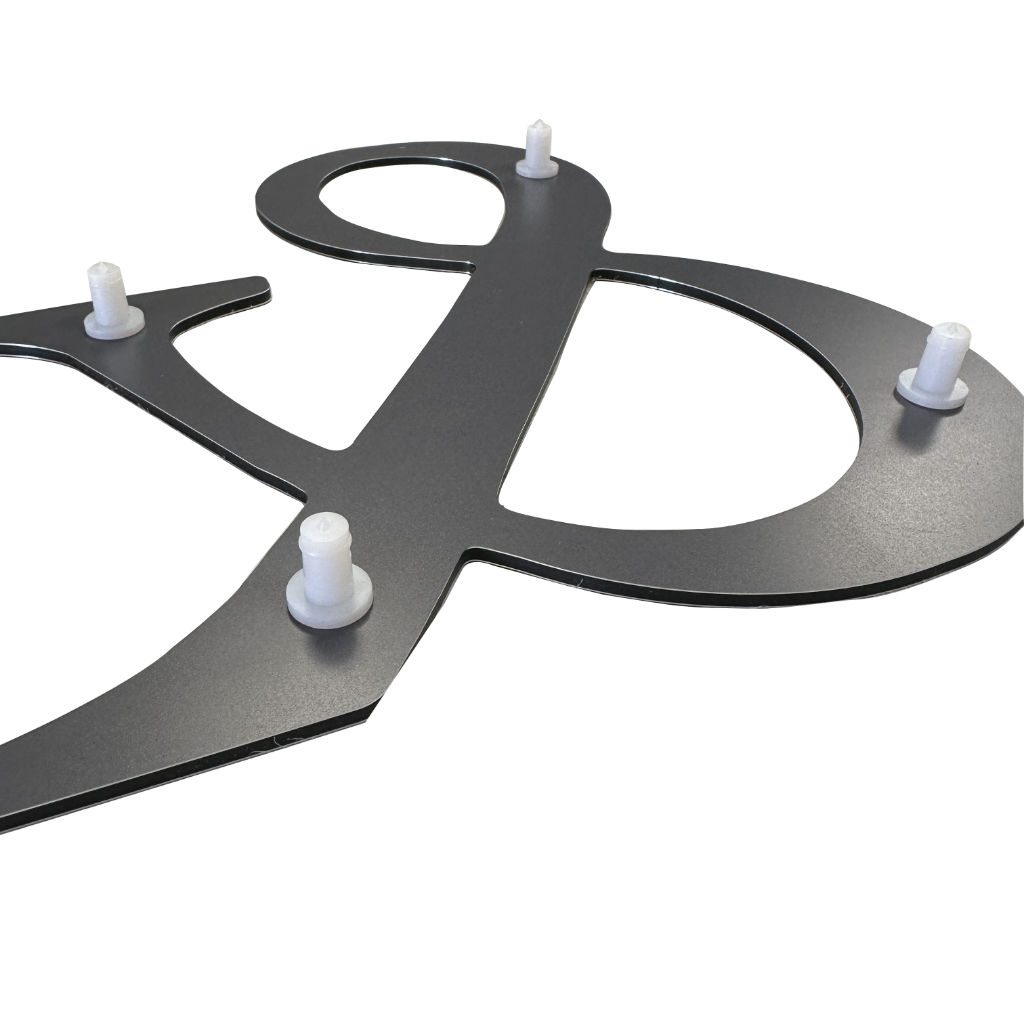

CNC routing isn’t just about speed, it’s a creative powerhouse. With the ability to execute intricate designs, layered textures and dimensional effects, fabricators can push the boundaries of what signage can look like.

- 3D Lettering: Add depth and drama to shopfronts and interior displays.

- Textured Panels: Create tactile surfaces that invite interaction.

- Custom Shapes: Go beyond rectangles, think curves, contours and cut-outs that reflect brand personality.

This opens the door for designers to experiment with bold concepts, knowing the machine can bring them to life with precision.

Seamless Integration with Digital Design

CNC routing thrives in a digital-first workflow. Most machines accept files from CAD (Computer Aided Design) software, allowing for seamless integration between design and production. This means:

- Rapid Prototyping: Designers can test ideas quickly and refine them based on real world results.

- Client Collaboration: Visual mockups can be translated directly into physical samples.

- Version Control: Updates to signage, whether for seasonal campaigns or rebrands, can be implemented swiftly.

For sign companies embracing digital transformation, CNC routing is a natural fit.

Built to Last

Durability is non-negotiable in signage. Whether it’s braving British weather or surviving high traffic environments, signs need to hold up. CNC routing contributes to longevity in several ways:

- Clean Edges: Reduces stress points that can lead to cracking or warping.

- Material Versatility: Allows for the use of robust substrates like ACM.

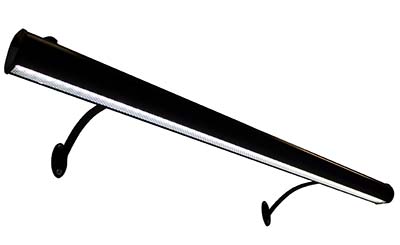

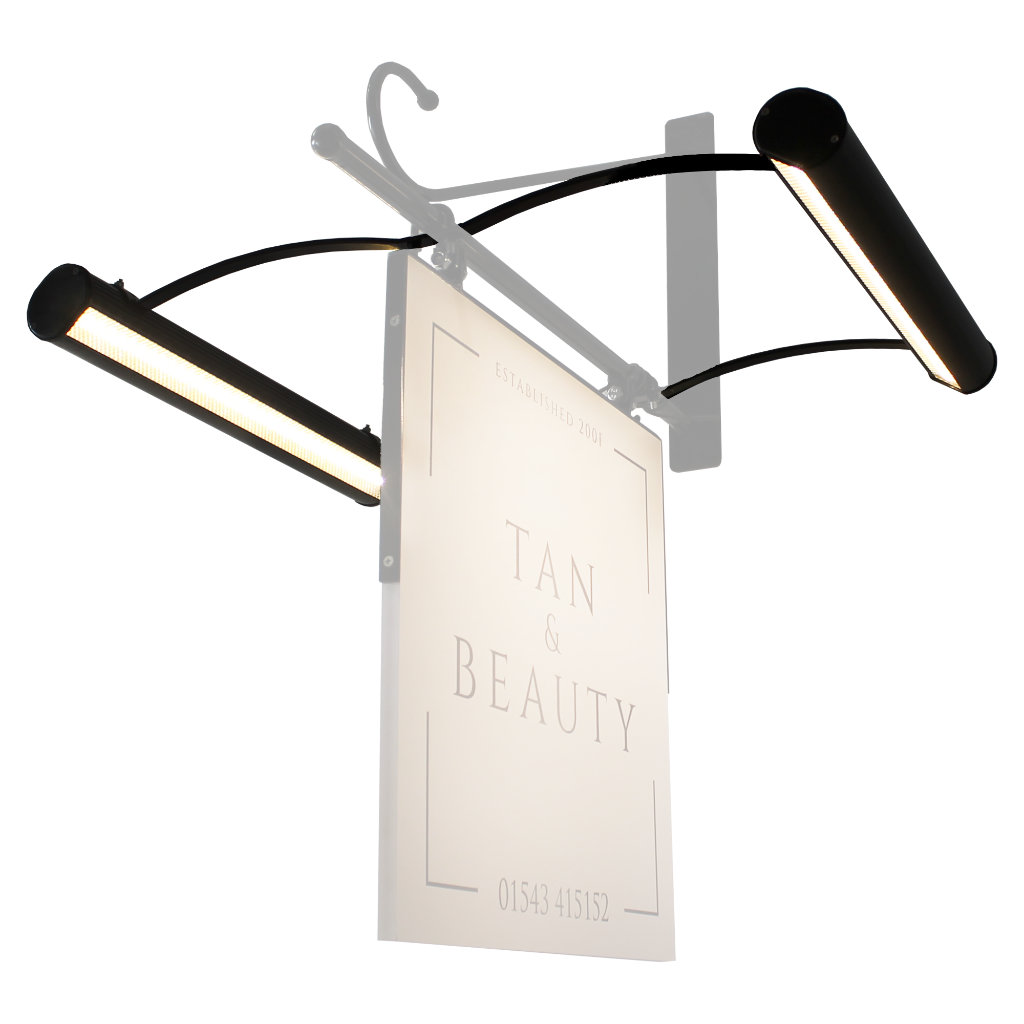

- Precision Fitting: Ensures components like LED housings or fixings sit flush, reducing wear and tear.

CNC-routed signs don’t just look good, they’re engineered to endure.

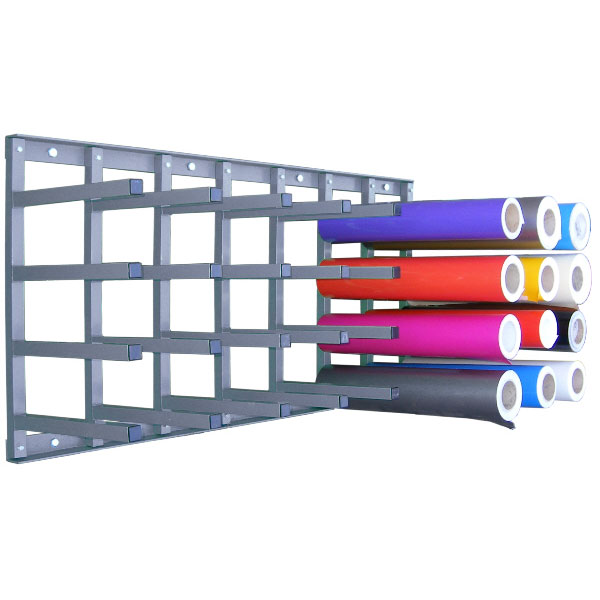

Sustainability and Waste Reduction

As the signage industry faces increasing pressure to adopt eco-friendly practices, CNC routing offers a path forward. By optimising material usage and reducing offcuts, it supports more sustainable production.

- Nesting Software: Arranges parts to minimize waste.

- Recyclable Materials: Works well with substrates that can be reused or repurposed.

- Energy Efficiency: Modern CNC machines are designed with lower power consumption in mind.

For fabricators committed to greener operations, CNC routing is a strategic asset.

Empowering Skilled Teams

Far from replacing craftsmanship, CNC routing enhances it. Skilled operators and designers are still essential, now with tools that amplify their capabilities.

- Upskilling Opportunities: Staff can learn CAD, CAM and machine operation, expanding their roles.

- Creative Control: Designers can prototype and iterate with greater freedom.

- Collaboration: Teams can work more cohesively across departments, from concept to completion.

Competitive Advantage

In a crowded market, differentiation is key. CNC routing allows sign companies to offer:

- Customisation at Scale: Bespoke designs without bottlenecks.

- Premium Finishes: High end aesthetics that command attention.

- Rapid Response: Faster lead times that win contracts.

For fabricators looking to stand out, CNC routing isn’t just a tool, it’s a strategic edge.

Real-World Impact: Tradesignz in Action

At Tradesignz, CNC routing has become a cornerstone of our production process. From flat cut letters to intricate illuminated signs, it allows us to deliver the quality and creativity our clients expect, on time, every time.

We’ve seen firsthand how CNC routing:

- Reduces lead times for custom signage

- Enables complex designs that elevate brand identity

- Supports sustainable practices through efficient material use

It’s not just changing how we work, it’s changing what’s possible.

Final Thoughts

CNC routing is more than a technological upgrade, it’s a

paradigm shift. It empowers sign fabricators to work smarter, design bolder,

and deliver better. As the industry continues to evolve, those who embrace CNC

routing will find themselves not just keeping up, but leading the way.

Whether you’re crafting a one off masterpiece or scaling up for a national rollout, CNC routing puts precision, speed, and creativity at your fingertips. And in a world where signage is both functional and expressive, that’s a game changer.