Behind the Bracket: How We Manufacture Projecting Sign Brackets

At Tradesignz, we don’t just make projecting sign brackets, we engineer visual statements that blend durability, design and trade expertise. From traditional wrought iron inspired scrolls to sleek modern profiles, our brackets are more than just hardware, they’re the backbone of the UK’s signage identity.

From Concept to Craft: Our Manufacturing Philosophy

Every bracket begins with a simple principle: form must meet function. We understand that signmakers need reliable, weather resistant brackets that also elevate the aesthetic of a shopfront. That’s why we manufacture all our projecting sign brackets in house at our Morecambe facility, giving us full control over quality, turnaround and customisation.

Our process is rooted in decades of experience. Tradesignz grew out of a retail sign making firm in the early ’90s, and we quickly realised the need for high quality, affordable signage hardware. What started with small batches from a local blacksmith evolved into a full fledged steel fabrication department and eventually, a dedicated manufacturing company.

Materials That Matter

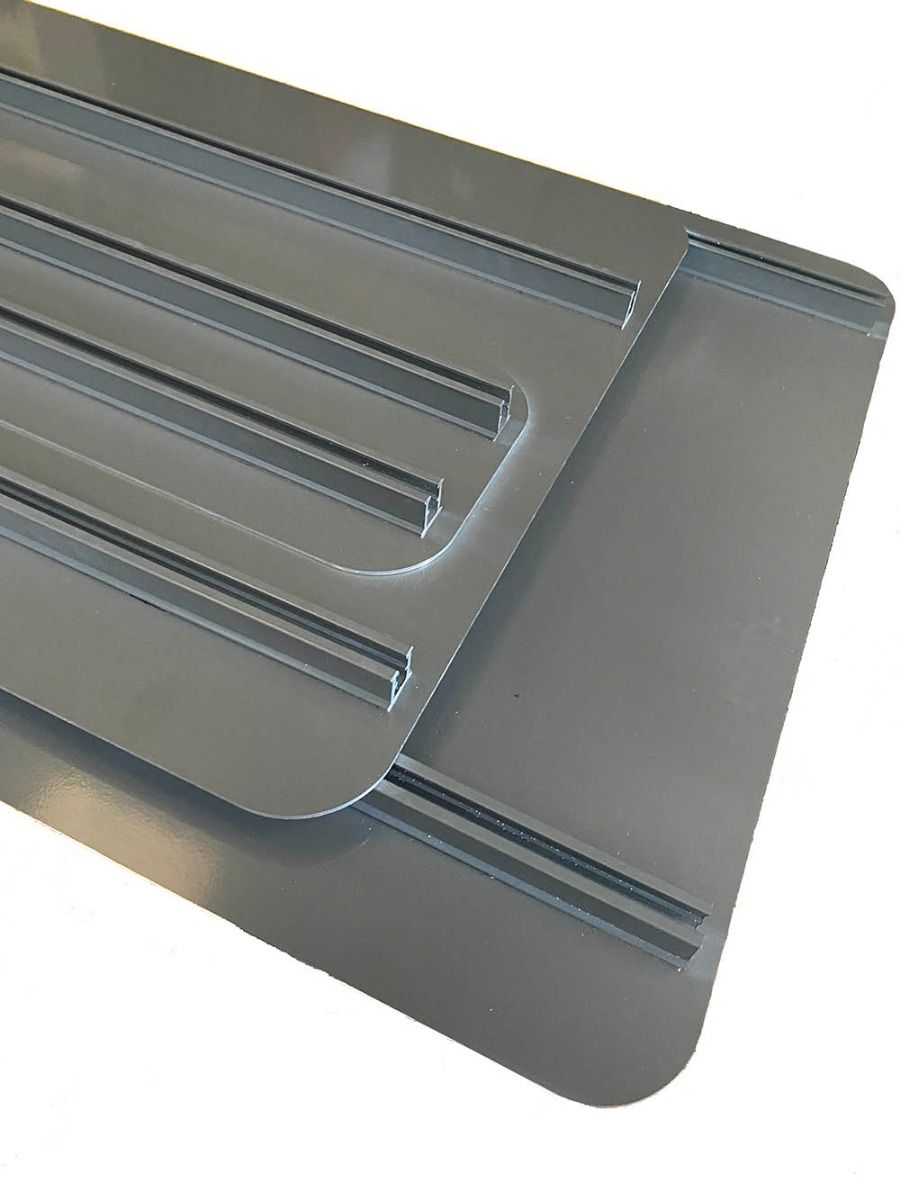

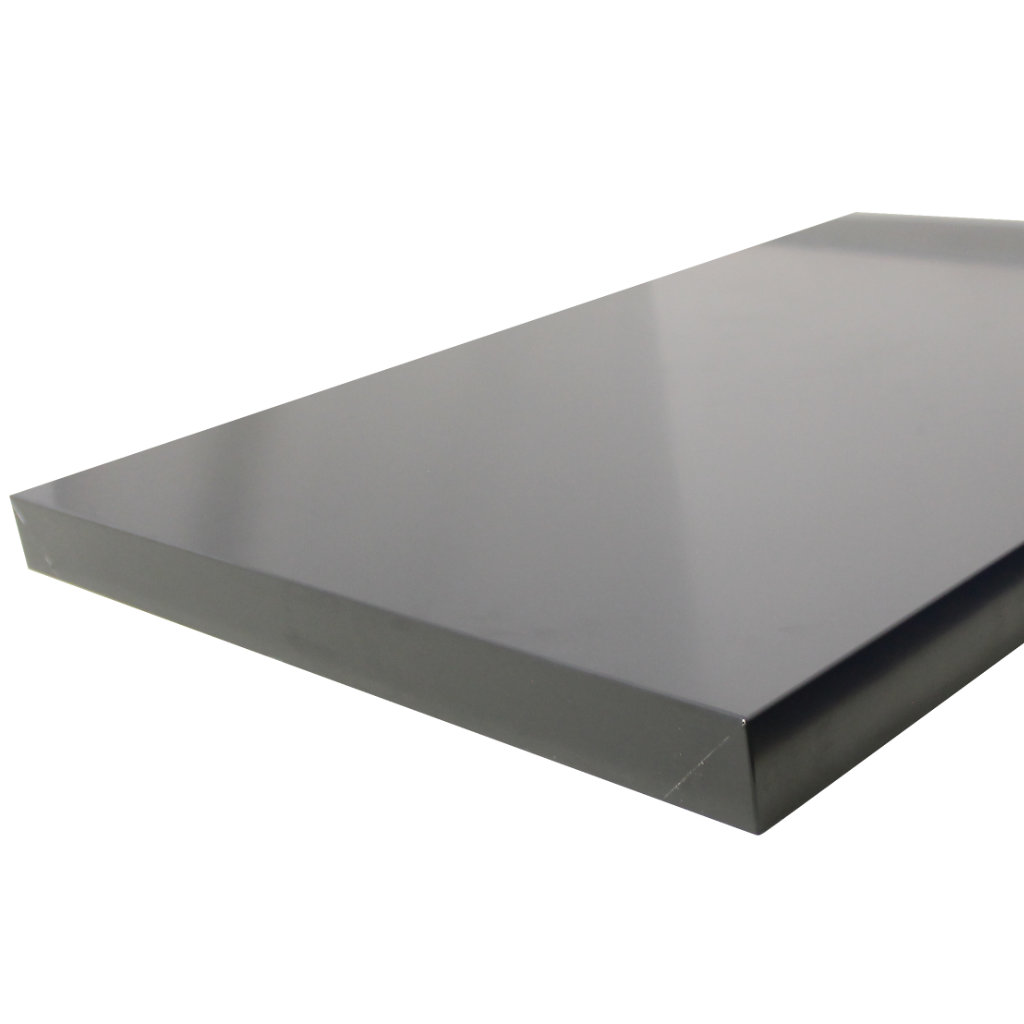

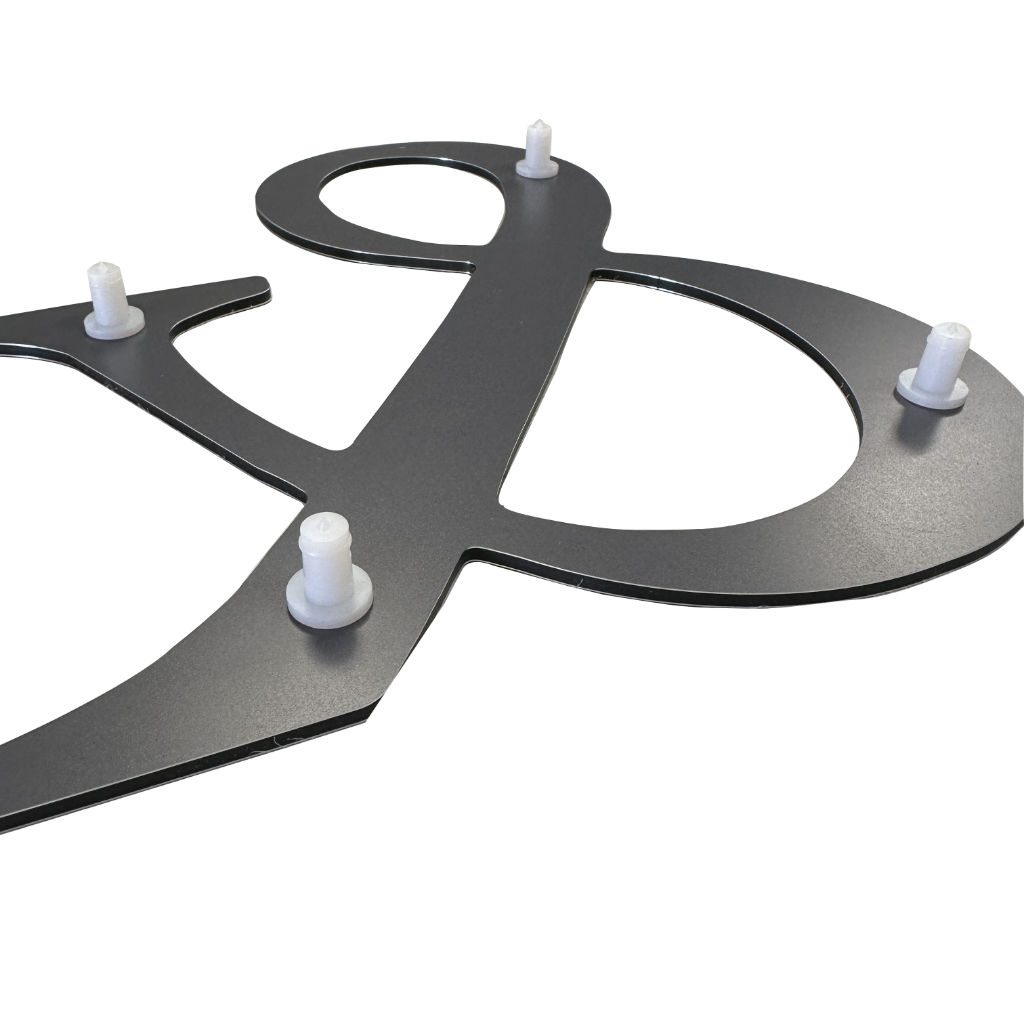

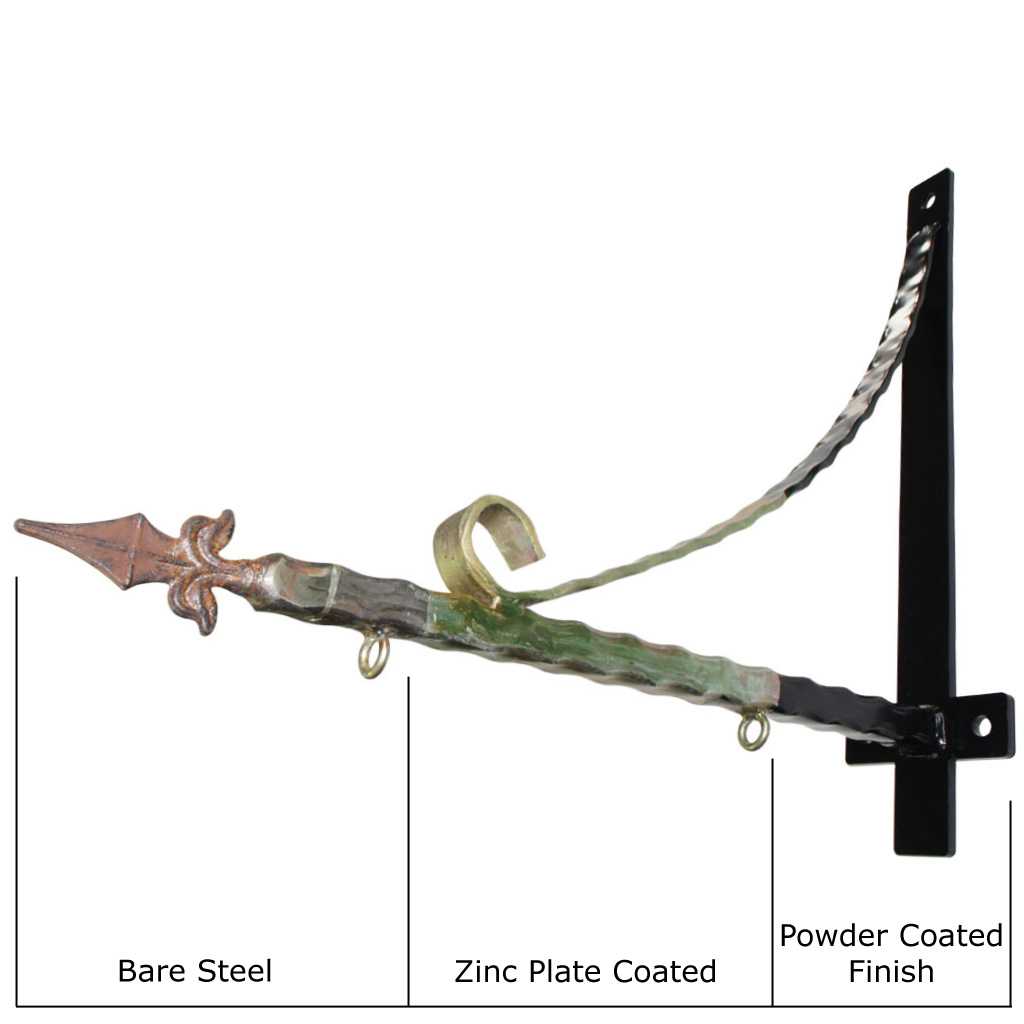

We start with heavy duty steel, chosen for its strength and longevity. Each bracket is precision cut and shaped to meet exact specifications, whether it’s a classic scroll design or a minimalist modern arm. Once fabricated, the steel components are zinc plated to protect against corrosion, then powder coated, typically in black or white, (though we offer other colours on request) for a sleek, durable finish.

This dual layer protection ensures our brackets can withstand the harsh British climate, from coastal winds to urban grime. It’s not just about looking good, it’s about lasting for years without compromise.

Bare Steel

Zinc Plate Coating

Powder Coated Finish

Styles That Speak

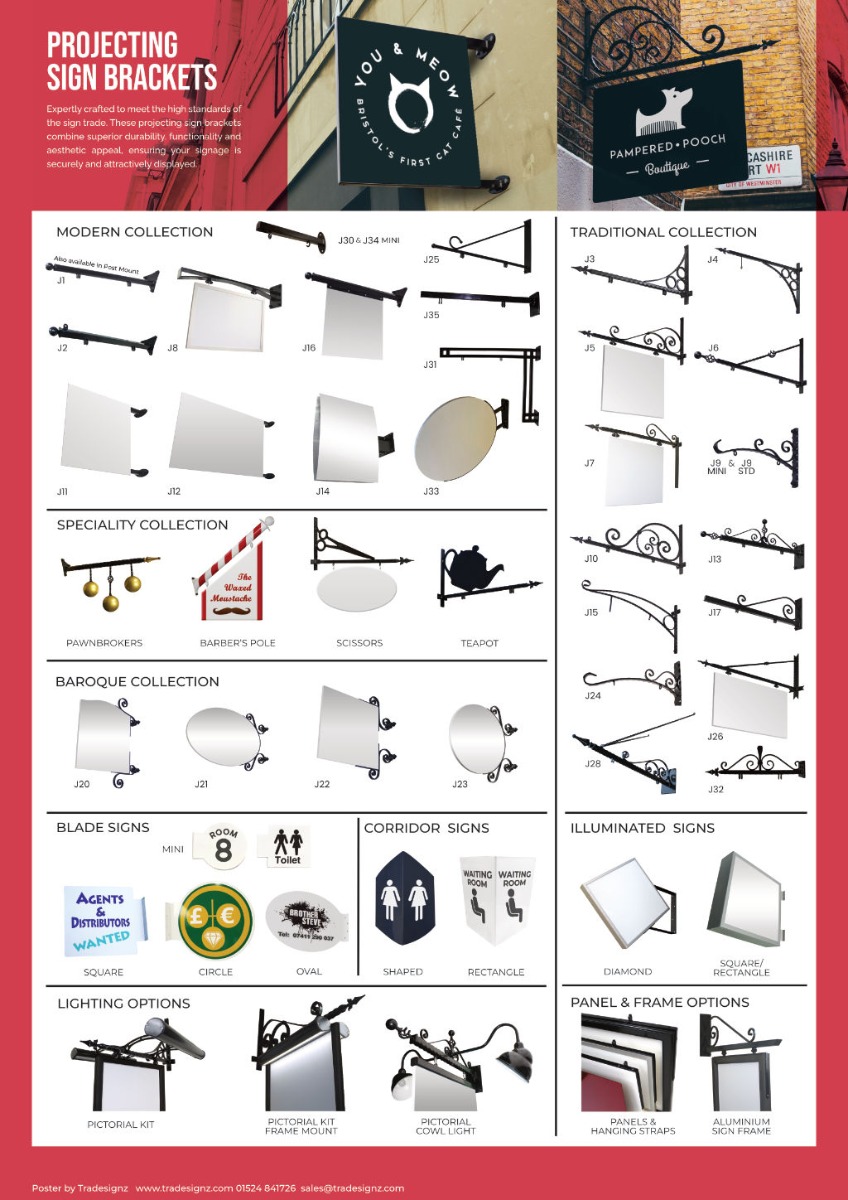

Our range includes over 30 bracket designs, each tailored to different signage needs. Whether you’re mounting a circular panel for a boutique or a rectangular sign for a pub, we’ve got a bracket that fits.

Some highlights:

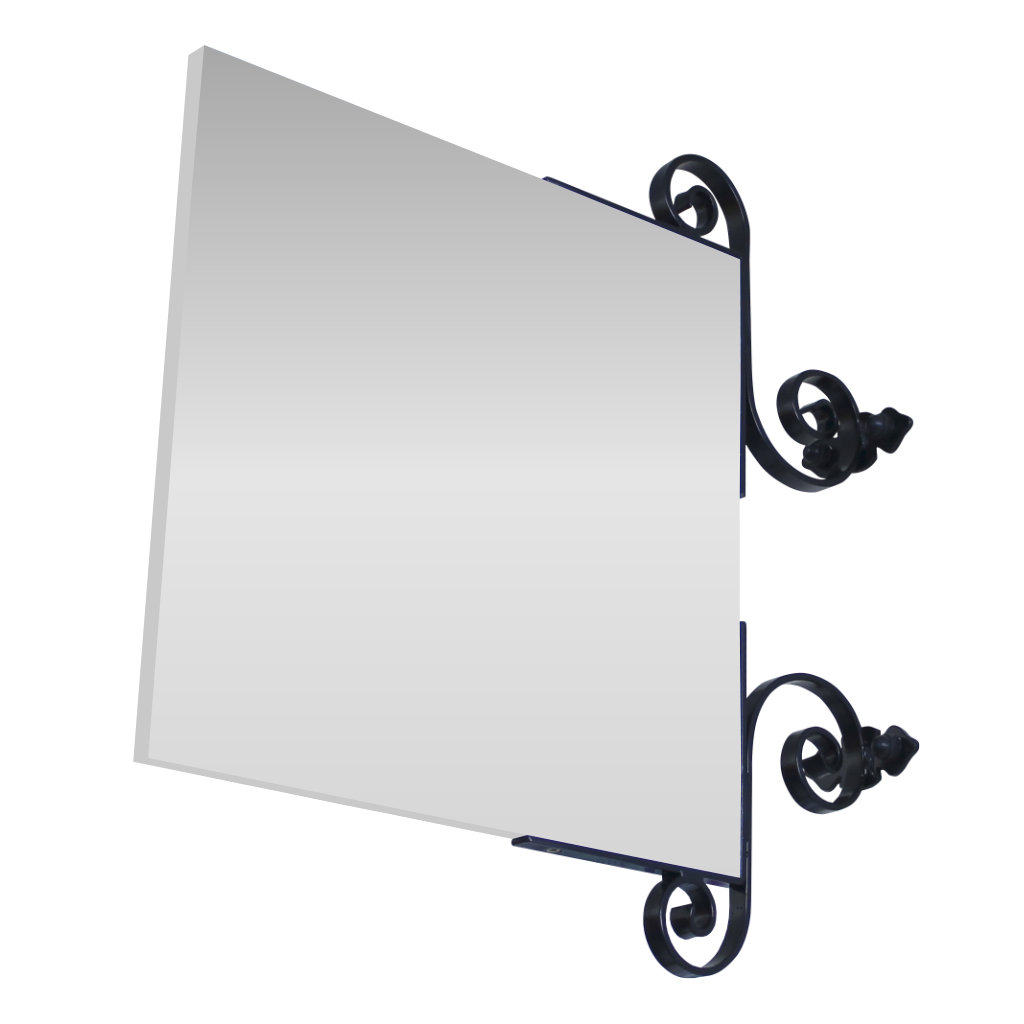

- Traditional Swing Brackets: Inspired by old style wrought iron, featuring hammered edges, scrolls and twisted steel.

- Baroque and Art Deco Collections: For businesses that want a touch of flair and period charm.

- Mini and Economy Brackets: Compact options for smaller panels or tighter spaces.

- Speciality Brackets: Including themed designs like pawnbrokers’ balls, barber poles, and even teapots.

Each bracket is supplied with wall fixings, making installation straightforward for signmakers and installers alike.

Precision Meets Innovation: CNC Capabilities

We offer a CNC routing and panel cutting service, using large format CNC machines, we can cut ACM, aluminium, PVC foam and more with pinpoint accuracy. This allows us to create custom shaped panels, intricate designs and tailored mounting solutions that align perfectly with your signage vision.

Whether it’s a one off bracket for a heritage building or a short run for a retail chain, our CNC capabilities ensure consistency, efficiency and creative freedom.

Why In House Manufacturing Matters

By keeping production in house, we offer:

- Strict quality control: Every bracket is inspected before dispatch.

- Faster turnaround: No waiting on third party suppliers.

- Greater flexibility: Need a custom projection or hanging eye spacing? We can accommodate.

- Sustainable practices: We minimise waste and optimise material usage through smart design and efficient cutting.

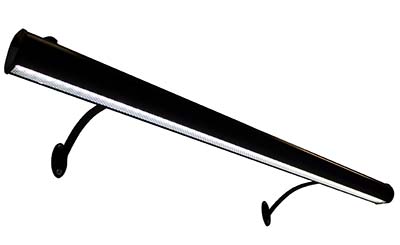

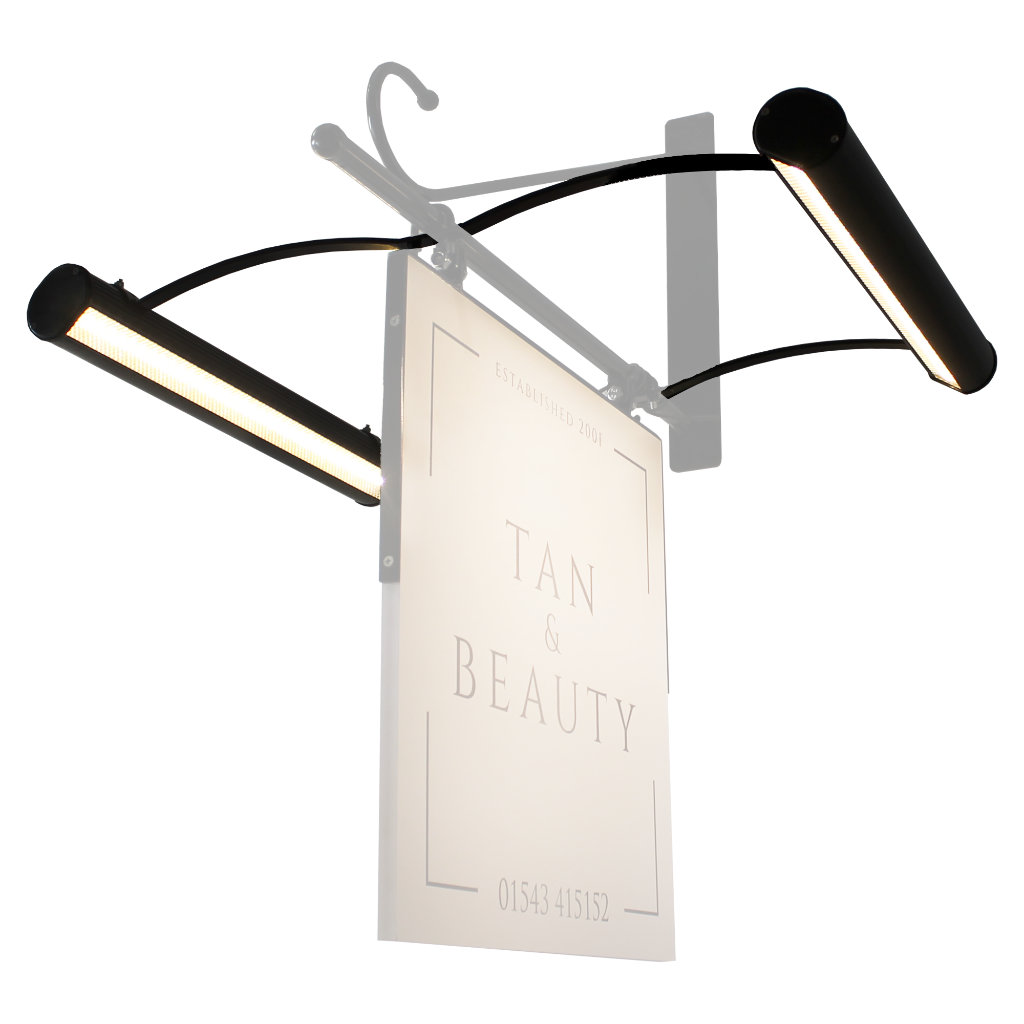

This hands on approach also means we’re constantly innovating. Our team regularly develops new bracket styles, lighting integrations and mounting solutions based on feedback from signmakers across the UK.

Built for British Weather

Let’s face it, signage in the UK faces a lot of wear and tear. Rain, wind, salt air and even the occasional pigeon can wreak havoc on poorly made brackets. That’s why our brackets are engineered to be robust and reliable, with finishes that resist rust and coatings that don’t flake.

We’ve tested our products in real world conditions and we’re proud to say they hold up beautifully. Whether your sign is on a bustling high street or a quiet country lane, our brackets will keep it secure and stylish.

Supporting the Sign Trade

Tradesignz isn’t just a manufacturer, we’re a partner to the sign trade. We understand the pressures of tight deadlines, bespoke client requests and the need for hardware that performs without fuss. That’s why we offer:

- Made to measure options

- Suitable fittings

- Illumination solutions

- Expert advice and customer support

Our goal is to make your job easier, whether you’re a solo signmaker or a national signage company.

Craftsmanship You Can Trust

Every bracket we produce carries the Tradesignz hallmark: British made, trade tested and built to last. We’re proud to be part of the Made in Britain network and we’re even prouder of the relationships we’ve built with signmakers across the country.

So next time you see a beautifully hung shop sign swinging in the breeze, take a closer look, you might just spot a Tradesignz bracket holding it all together.